Investing in an egg tray production business is a brilliant idea. You can help people get rid of their paper waste and use it to manufacture egg trays. Since all supermarkets and grocery stores sell their eggs in the paper tray, it comes without saying that you can set up a very lucrative business. However, you should do your research properly before buying your egg tray machine, in order to get the best value for money.

Before you start looking into global trading directories and business pages, you should take a look at Beston Machinery. This site may be the only one you’ll ever need to find the least expensive egg tray machines sale. Their offer is quite impressive, and you have the option to ask them for a quote on any of the machines they showcase on their website.

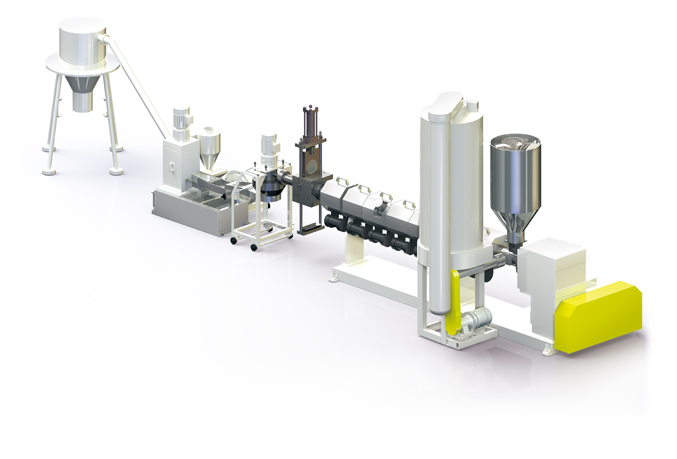

Before you send in your inquiry, you need to know what kind of machine you’re looking for. This means you need to calculate the required output per hour or per day, in order to purchase the right pulp molding equipment to cater to the needs of your clients. As in the beginning, you won’t have any clients, you should try to estimate the potential of the market. Decide where you’d like to sell your egg trays, and find out how much those grocery stores and supermarkets sell, as well as how many eggs the farmers you’d like to target produce on daily basis.

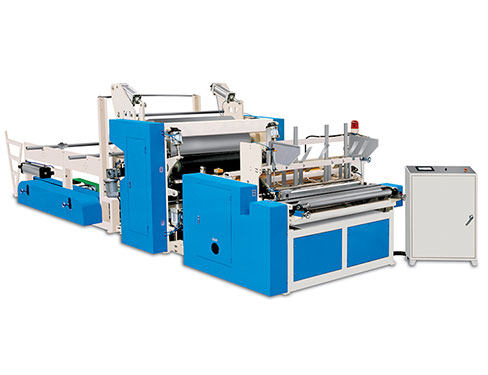

Based on these figures, you should be able to calculate how many trays you’d have to produce per day, in order to reach your targeted market share. Next, you’ll have to compare all egg tray machines on the website of Beston Machinery to see which models suit your needs. Furthermore, you should decide whether you want to go for a semi automatic egg tray making machine or you’d be better off with a manual one. Keep in mind that large production volumes may require a certain level of automation. You can’t work faster than a machine, so buying a manual one may not be the best idea ever.

Although manufacturing egg trays can be a very profitable activity in itself, trying to lower the cost of your equipment can help you start your business on the right foot. Keep in mind that you’ll need to invest in marketing and promotion, in rent and distribution, as well as in collecting paper waste from your local community. Why not save money wherever possible? Ask Beston Machinery for a price quote and you’re going to be able to compare it with the prices of other suppliers. You will find the best egg tray making machine manufacturer.

Anyway, if you don’t know how to calculate the needed parameters and technical specifications of your egg tray making equipment, you should get in touch with a Beston Machinery sales representative to ask for professional help. Even though the company operates in China, they have clients from all over the world, so they are able to give you good advice to help you start your business the right way. They have exported egg tray machine in the Philippines, in India, etc.