There is so much biochar production equipment available today, it’s hard to choose the right system. You may not realize how difficult it is to obtain a reliable pyrolysis plant or even a pyrolysis machine until you start to look. These are designed to convert many different materials into burnable fuel. For example, if you have an abundance of plastic that you can put into these machines, you can save a considerable amount of money on the cost of fuel. You can also sell charcoal, and also bio oil, to businesses that need. These are all products that are available to those who own and use biochar production equipment.

How Does This Type Of Equipment Work?

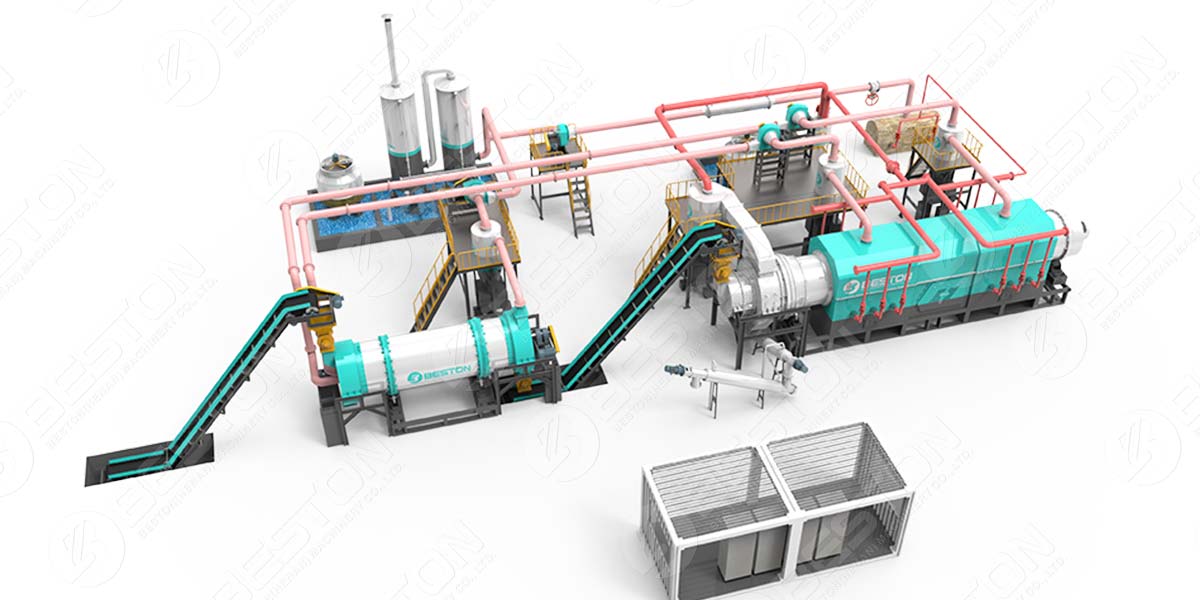

This equipment is designed to provide you with an abundance of burnable fuel. You can sell this to other people, businesses, and companies like yours that may use the bio oil and fuel to power their vehicles. Charcoal is always an abundance with companies that are interested in marketing this to people that need it for cooking or for fuel. Essentially, this biochar machine will take organic material, rubber, plastic, and even municipal solid waste and converted into fuel that you can use or sell. It does so using the pyrolysis process which can be completed in just a few hours. In the absence of oxygen, a chemical change will happen, converting this material into the fuel that you can use or sell to others.

How To Get One Of These Machines

You can get these machines very quickly from a variety of sources. Many of these companies are well-known for providing many different options. Some of these companies will offer you exceptional deals on the charcoal making machine which you can use at any time. Whether you get one of them, or multiple units Be able to access these systems which will give you the ability to convert these materials to fuel that you can use or sell.

How To Profit From Biochar Production Equipment

Biochar production equipment can be very profitable for your business. It will only take you a few minutes of your time to evaluate the different systems. Each one of them will be produced by different companies that will create both large and small models that you can use. From small machines that will process minimal amounts of material, to entire pyrolysis plants, you can get the one that will work best for you and your business. All that takes is a little bit of time to do a few evaluations to find the right one.

Pyrolysis machines have been around for many decades. Advancements in technology have made them very easy to use on a continual basis. If you have an abundance of rubber, municipal solid waste, or plastic, you can start your business immediately. Just make sure that you are obtaining one of the more efficient systems for converting these materials into fuel that is solid or liquid informed. For more information, start looking for bamboo charcoal making machine and plant manufacturers that can offer you an exceptional deal.