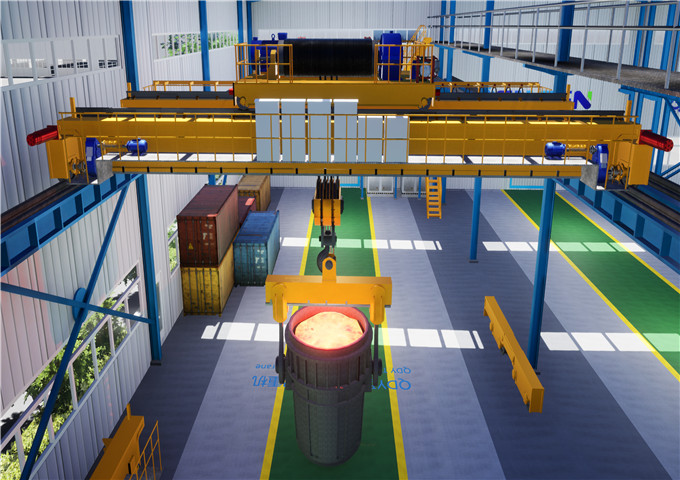

It is no surprise how a crane works(мостовой кран цена завода). Though, when it comes to carrying molten metal it is important to ensure that the overhead crane you buy has very specific and reliable features in place to prevent damage. Beyond needing to know the tonnage of molten metal that will be carried, it will also be important to know how to prevent sway. While some movement will be inevitable and necessary, over sway can lead to loss of molten metal, damage, or injuries.

Metallurgical overhead cranes(краны мостовые металлургические) specifically assist in fully lifting molten metals or even non-metals, hot metals, or other items. The overhead crane usually has a double girder structure. This helps stabilize the movement of the molten metal so that it is well-maintained along one path. Go with improved configurations that include this double configuration for greatest stability, management and control. The crane needs to in turn supply a rated capacity to lift. Look at how much weight the cranes you are considering will be able to lift. It will help determine whether you need to look at a different crane or not. Take a look at its working level as well. Stick with an M7 or more. Go with the best anti-sway you can buy, because this is key for safe and effective use of a metallurgical overhead crane.

Do also take into consideration if there is any type of automatic positioning tech built into it. These days, most cranes are boasting more and more features than ever before. In many cases, they are tools that will help boost your productivity, safety, and effectiveness. It will all help as a step in the direction toward automated metallurgical movement. Those are just the main features to consider buying when looking at overhead metallurgical cranes(металлургический кран). Think about today as well as the future.