This Is How The Cold Rolling Embossing Machine Works

In simple terms, the entire process of embossing may be defined as the entire process of transferring particular shapes and design through to an iron bar. One of the ways to emboss an iron bar is to try using brute force to make beautiful and intricate shapes. However, using brute force is inefficient and takes time and effort. One other way is by using an embossing machine because it helps make the whole process much easier and easierh. Here is the website, which will give you more information http://www.ellsenwroughtironmachinery.com/wrought-iron-embossing-machine/.

There are multiple methods to emboss iron bars but the cold rolling process with the aid of cold rolling opposing machine is preferred over hot rolling process as cold rolling does not involve warming up the the iron bars for embossing. Heating up the iron bars again affects their strength and therefore, the cold embossing process is preferred around the world across the hot rolling process. From the article below, you will get to find out the way a cold rolling embossing machine works.

As being the name suggests, the technique involves embossing cold iron bars without heating up the bars to make them malleable. Within the cold rolling process, extremely high pressure is commonly used for transferring the desired shape and design onto the iron bars. On the other hand, the new rolling process involves heating up the iron bars and which makes them malleable enough to transfer the design and style on to the bars.

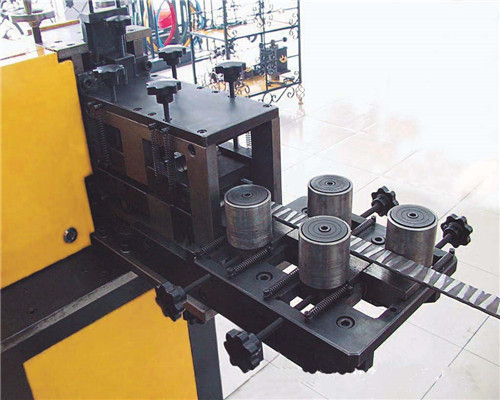

The cold embossing machines have a feeder table which is used for guiding and accepting the content into the machine. After the bars have been put on the feeder table, the guides are adjusted through the operator in the machine based on the size of the information. With regards to the adjustment process is concerned, the guides are adjusted through the operator considering the height along with width in the bar that is going to be embossed.

After the bars are fed into the machine, high pressure is exerted on to the die to transfer the design and style from your engraving die for the bar. This immense pressure helps in transferring the style and shape on the iron bar. When the embossing has been completed, the bar is straightened with the aid of straightening section in the machine. Flexible rollers are used inside the section for strengthening the iron bar. More information about the working process, please have a visit at this site: http://ellsenwroughtironmachinery.com/.

There are a variety of manufacturers all across the globe that manufacture and then sell the cold embossing machines on the market but you should select the right type of machine to be sure that the device keeps working without any issues for a long period of your energy. There are a number of important features that one needs to consider to select the appropriate embossing.

A few of these features include the capacity in addition to capacity for the embossing machine to handle square, flat and also round bars. The equipment must also feature adjustable speed and really should be easy to keep. Of course, it should also be energy efficient to make certain that the process remains cost effective.

Overall, this is the way the cold embossing process works. It is very important select the right cold embossing machine to handle the embossing process without the issues.

Other wrought iron machines like blacksmith power press machine, please visit: http://ellsenwroughtironmachinery.com/power-press-machine-sale/.