The conversion strategy is uncommonly fundamental and clear. It implies the warm rot of plastics at big temperature without oxygen. The totally altered blueprint can guarantee the entire method is to a high degree environment neighborly. Exactly when the strategy is done, we may have plastic oil, carbon dull and to some degree burnable gas. And every choosing things have a broad assortment of employments.

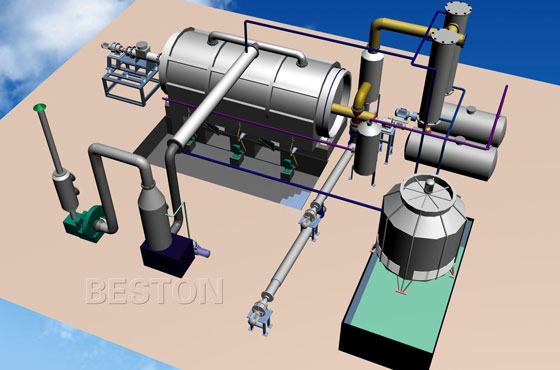

The plastic into oil machine for sale is an impeccable hardware used for recycling waste plastics. It grasps the latest conversion advancement at which plastics may be totally changed over into important resources. Is it pleasant to know recycling plastic into fuel oil-conversion machine?

Is it great to know first the conversion machine. The plastic oil may be utilized as fuel oil as a part of various business wanders and can moreover be refined. The carbon dim can be utilized for making improvement obstructs with earth or utilized as fuel.

At the time oxygen, oil gas, and high temperature joined in the working procedure, a stunning impact will be subject to happen. So create security contraption the certification for the standard working of the plant. Being in the field, the greater part of the plants are furnished with front line security devices, for instance, the auto ready structure for high temperature and weight, auto weight discharging system at emergency circumstances and putting out flames contraptions. These prosperity contraptions may guarantee safety of 100% in the era strategy.

The plastic pyrolysis plant cost has assorted working structures and recipient taking care of cutoff points from even 6 ton to 50 ton for consistently. On the off chance that you have extraordinary interest, we can in like manner give you revamp thing.

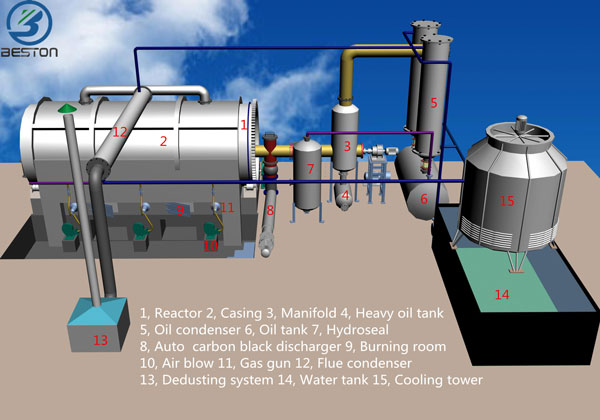

Plastic conversion process using conversion machine

The mixed plastics will be pulverized and reliably energized into the reactor of conversion utilizing managing machine. The supplies can be pre-warmed in the midst of the going on the technique, and a melting point that is low plastic like can be pyrolysis of waste. The HCl can be then slaughtered treated thereon separation with various materials.

The consistent temperature warming system supplies warmth to the reactor conversion. The unrefined materials are industriously supported into the reactor conversion and spread by the structure, finishing conversion process with the high-adequacy catalyst.

The conversion oil gas is changed into splendid fuel oil and a little measure of ignitable gas in the wake of taking after systems, for instance, incomplete refining separation, settled bed discretionary de-waxing gas and catalyzing et cetera.

The burnable gas is in the end used as fuel towards the framework in the wake of scouring, which satisfies warm criticalness self-supporting. The gas in the wake of being reproduced can be qualified evacuated after the gas refining strategy.

The little measure of strong improvement produced using the response bring up routinely evacuated out of the response point, and that might be further orchestrated into fuel stick.

Squander plastic pre-treatment structure

Grungy material pre-warming framework

Persisting temperature warming framework

HCl holding structure (discretionary relying on material)

Persistent conversion framework

Ignitable gas cleaning structure

Gas filtration structure

Staying foul free treatment framework

Control subsystem

Get more about conversion machine of plastic to oil today. Have you gotten something from the realities about plastic to oil conversion machine for sale?

One of the biggest factors that goes into making paper egg trays so expensive is the shipping cost. Egg trays are lightweight, but their bulky shapes make them a costly item to ship. By manufacturing all egg packaging materials on site, you can save thousands of dollars every year just by cutting shipping costs alone. So, buying egg tray machine is a good investment.

One of the biggest factors that goes into making paper egg trays so expensive is the shipping cost. Egg trays are lightweight, but their bulky shapes make them a costly item to ship. By manufacturing all egg packaging materials on site, you can save thousands of dollars every year just by cutting shipping costs alone. So, buying egg tray machine is a good investment.