The main differences between the semi-automatic and the full automatic concrete batching plant are to do with the control-system, while the other equipment will have no differences. The fully-automatic control systems make use of a full-automatic control system while the semi-automatic control system makes use of a centralized control-system.

What Are The Differences Between These 2 Types Of Concrete Batching Plant On The Operation Of A Control System?

The rated-production efficiency for the semi-automatic and fully-automatic is exactly the same, the difference is associated with the styles in which they operate. When it comes to the fully-automatic concrete batching plant a button will be pressed so that materials can be discharged into the screw conveyor that comes from the cement silo. This is followed by the automatic unloading of the materials into the concrete mixer from the scale hopper. In the entire production process these operations are completed by pressing one button that is easy, convenient and suitable for a concrete-batching plant with the need for fewer people. More operating information about the semi-auto and fully-auto concrete batching plants on http://aimixconcretebatchingplant.com/semi-automatic-concrete-batching-plant/.

The semi-automatic concrete-batching plant that uses the centralized system is not as simple and is completed using a step by step process that involves pressing buttons at specific times. This means that when it comes to feeding materials through the production process, the feeding button will need to be pressed in order for the materials to be discharged in the scale hopper. This needs to be followed by pressing another button known as the “discharging button” in order to discharge these materials in the concrete mixer. For this reason these centralized control systems necessitate more workers in order to operate. Buy high-quality semi-automatic concrete batching plant in Aimix Machinery Co., Ltd.

The Automatic Batching Plant

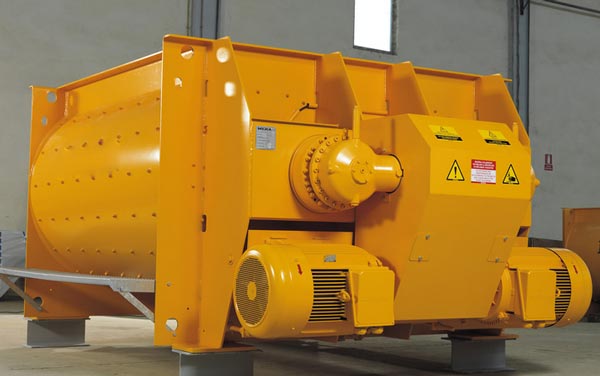

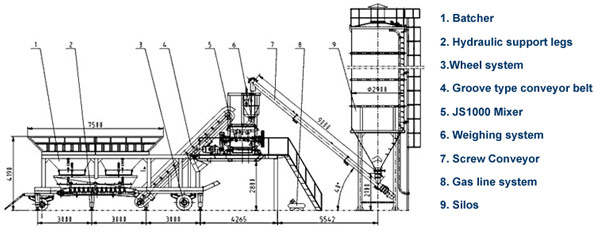

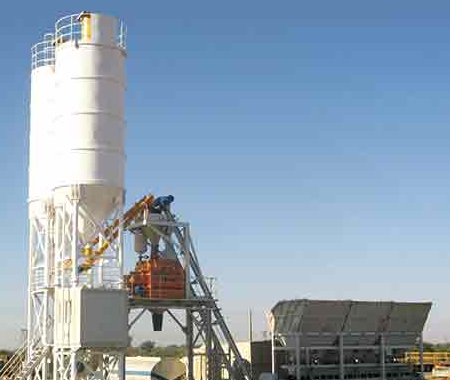

An Automatic Batching Plant is typically utilized to transport ingredients that make up concrete that need to be combined in order to produce concrete or they are used to prepare the concrete for the next stage of processing. These batching plants that run automatically means that the output can result in 20 up to 25 cum per an hour. This is accompanied by a reverse-blade technology which enables the mixture to undergo thorough mixing each time. These plants more than often will include pneumatic wheels that offer better mobility so that they can be moved from one place to another in an industrial or commercial environment. In addition they also come with an optional?weighing system that features electric-load cells. Click here http://www.aimixconcretebatchingplant.com/ to buy the best semi-auto concrete batching plants.

The automated water dispenser on this type of batching plant offers fantastic advantages in regards to handling the best water spraying throughout the processes involved in concrete mixing. In addition, the automatic plant offers an easy discharge process from the concrete pump along with the tough rider ensuring that the right discharge height will always be maintained. Along with the hydraulic components, the entire processing may look simple but is able to handle all the complex tasks. The automatic plants usually have a body that is made out of stainless steel that offers outstanding durability as well as making the plant resistant to general wear-and-tear.