Information About The Rice Husk Carbonization Machine

In the not-so-distant past, rice husk was a form of biomass waste. At some point, there was no real value for it until the invention of the rice husk carbonization furnace.

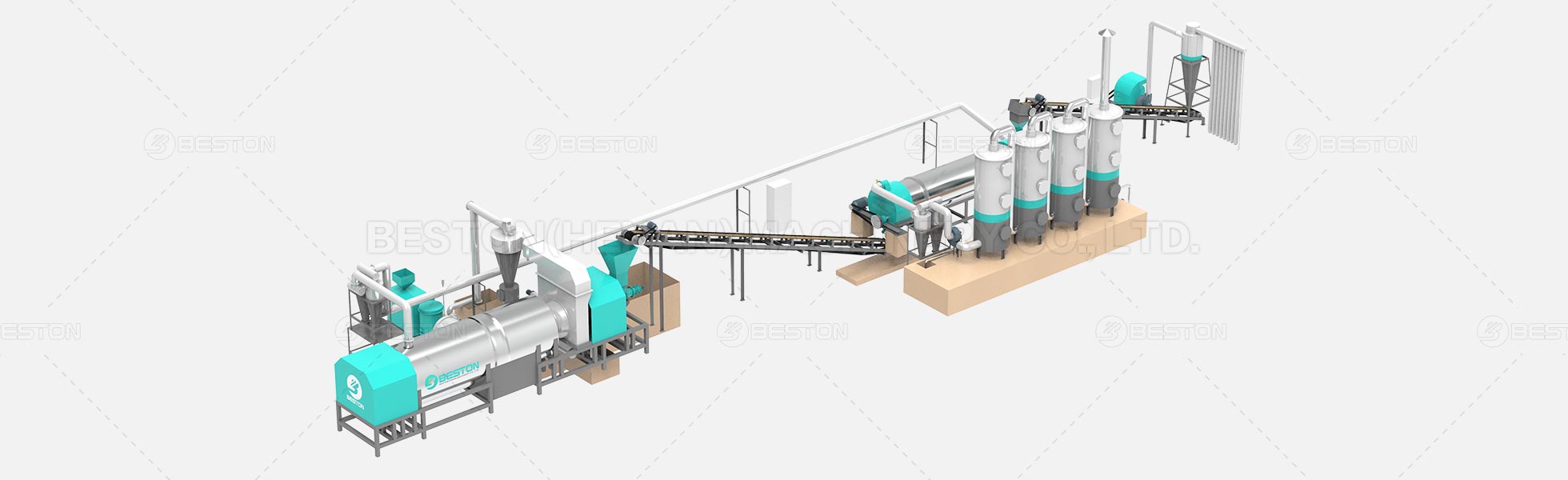

As progress keeps occurring, there is new and improved technology in the industry. Due to its design, the carbonization(planta de carbonización) furnace is said to be a breakthrough. If you purchase from the leading manufacturers, you’re sure to be in good hands with superior design and working mechanisms.

These machines function on a rather basic concept. There is a high temperature that produces fuel gas, charcoal enrichment, and sulfur emission. At the core, the temperature soars to break down the raw materials. This occurs when combustible gas is generated at a high caloric value.

After operating for about 30 minutes, the heating source is replaced. This is done by coal, natural gas, or even wood. If it didn’t strike as yet, this is the perfect way to consider the environment in operations. The machine recycles heat to not only protect the environment but also save energy.

After the processing phase, you’ll be rewarded with wood vinegar, charcoal, and tar. All of these can make you another profit from the markets. Since there is always a continuous energy demand, the caloric value is high. Some end products can also be converted into warmth, used in BBQ, and for cooking.

Besides the advanced technology, there are several economical benefits. The charcoal produced from the rice husk carbonization (máquina para hacer carbón vegetal)furnace meets some of the highest EU standards. The leading furnace manufacturers also ensure that pollutants are not produced at all during the entire process.

The following are some common requirements for raw materials:

* The moisture for all raw materials should not be less than 20%.

* The overall temperature of the production process should remain anywhere between 400 and 600 degrees centigrade.

* When being discharged, the temperature should not be higher than 30 degrees centigrade. This ensures that the workers are safe and protected from accidents at all times.

When you purchase these types of machines, you’ll need to ensure that you purchase from the best. As such, the following services should be offered:

* Technical data and related information should be provided by the manufacturer(China Beston Group).

* You should be offered a special factory tour to see the end products.

* A plan should be provided for both client project and site.

* Reasonable shipping suggestions and freight should be offered.

* Manufacturing should be supervised for higher quality products.

* Delivery should be quick and tracking should also be offered.

* Manufacturer engineers should be sent to ensure proper testing, installation, and training for your workers.

* Your manufacturer should also call from time to time to ensure that there are no issues with the plant.

As we conclude, we have just looked at everything you’ll need to consider when purchasing the rice husk carbonization furnace. These machines (https://www.bestoneco.com/hornos-metalicos-para-hacer-carbon/)were designed with the environment in mind. So, if you’re thinking of purchasing there’s no need to worry!