Pyrolysis Machine – Make Sure That They’re of the Finest Quality

Despite the fact that plastic is without a doubt indispensable to society in our day-to-day existence,the actual plastic can give individuals that are environmentally minded cause for concern, as it is not much of a bio-degradable product. We could obviously do recycling plastic granulator design, and that is crucial if we are to safeguard the earth, guard valuable non-renewable energy resources (which in turn the majority of plastics are made from), and provide a cost-effective opportunity for producers to produce plastic items. Typically when producing plastic goods by using recycled material it’s more cost-effective for producers as opposed to making use of “from scratch” supplies. Before investing, learn the tyre recycling machine price.

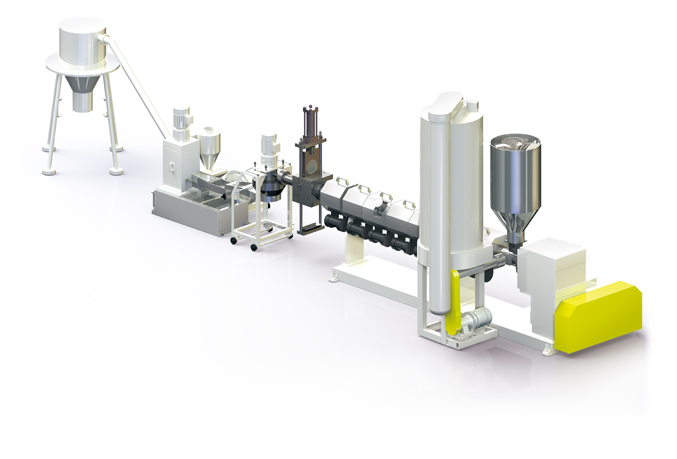

We have to have appropriate technologies in order to make recycling plastic material feasible. Granulator blades give you the best way to recycle plastic in order that the industry experts are able to use recycled materials when producing goods.

Most people knew that because plastic is not a biodegradable material it has to be recycled. Large amounts of various types of plastics are often found at recycling centers, waiting to be recycled and used in different plastic industries. plastic recycling granulator design for several reasons is crucial. Not only does recycling help reduce the environment’s pollution level, but it also increases the profitability of companies in the plastic industry. There is a complete set of high quality tyre to oil plant.

How do granulator blades work?

Granulator blades are employed during the recycling process in granulator machines. The blades are extremely sharp, and they’re made use of in addition to a rotor and high-speed engine. Old plastics are cut into very tiny bits inside the machine by way of the blades, which are then recycled in the manufacturing of numerous plastic items. In reality, the plastic recycling market could hardly function at the best possible level or productivity without using good quality blades.

The plastic recycling granulator design rotor is within some sort of chamber which is cylindrical in shape, and contains an electric motor linked to it. The granulator blades are extremely robust and are coupled to the rotor itself. As soon as the machine is switched on and the motor actually starts to turn, the blades rotate at extremely high speeds, which in turn slashes the recycled plastic particles into small granules. The size of the particles or granules is governed through a solitary filter beneath the rotor that’s got different sized holes dependent upon the plastic scrap size requested. View the tire pyrolysis plant project report now.

The necessity of granulator blades to the plastic recycling granulator design

If the plastic recycling granulator design is to continue on, there will always be a market for granulator blades simply because the plastics industry could survive without them. Nevertheless, it’s vital to locate a suitable producer of these blades, to make sure that they’re of the finest quality. Even though several manufacturers are undoubtedly able to produce granulator blades, one can be absolutely confident in the level of quality.